Coordinate punching

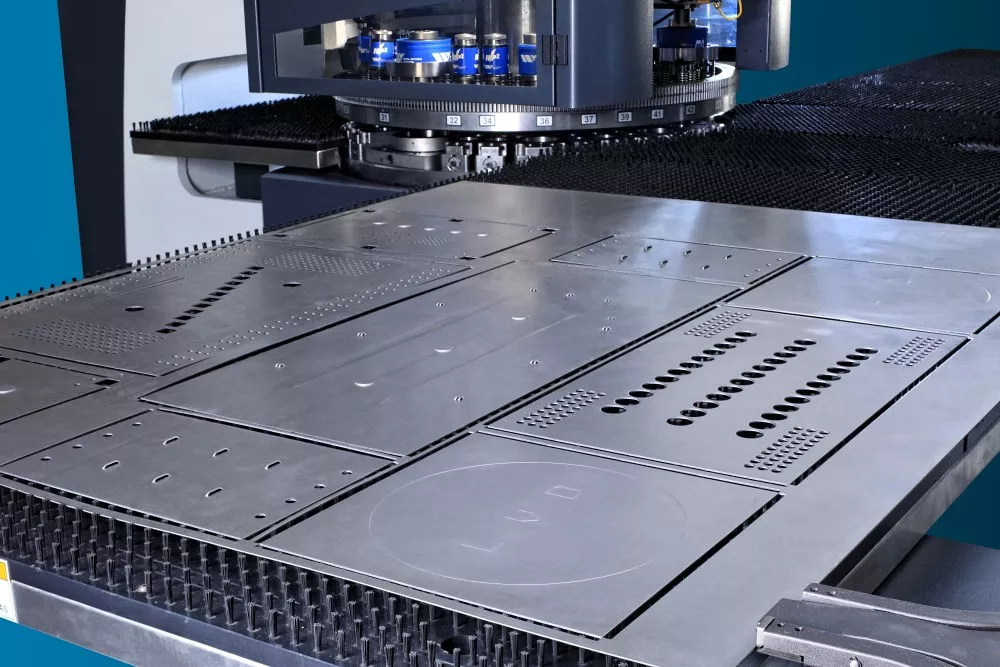

Technological process used for making openings and cuts in sheet metal with high precision and repeatability

price from: 4.7 RUR/item

order a service

Technology

Coordinate metal punching is a technological solution presenting an effective alternative in cases when price and cost optimization are considered important factors by the client. This technology allows for metal sheet production that otherwise would be more expensive to secure with the help of laser cutting.

Via control panel of the preprogrammed punching machine, movements of the punching tools are precisely directed, the latter having various shapes and sizes for executing a number of operations like punching holes, cutting contours, rolling threads etc. The press provides creation of flanging openings with different parameters including hole diameter depending on material thickness.

Show more

stages of work

our approach

01

Receiving

the request

the request

Get in contact with managers as indicated on the company website: fill in the application or make a call.

02

Analyzing

the information

the information

Provide a drawing or a sketch in order for our experts to assess your information.

03

Anticipated workload

evaluation

evaluation

On the basis of information received, we undertake time and cost planning necessary for order execution.

04

Conditions

and timeline

and timeline

After discussing the details, we approve the specification and sign the contract.

05

Manufacture

preparation

preparation

A set of activities is introduced for timely and high-quality design of new products and their putting into production.

06

Order

execution

execution

We proceed with order execution on the basis of information received in full compliance with the customer requirements.

07

Shipment and

delivery

delivery

Ready-made products are delivered to the customer’s address within the shortest possible time.

gallery

examples of work

Contact us

leave a message

Need expert advice or get questions? Contact us, and our managers will get back to you shortly.