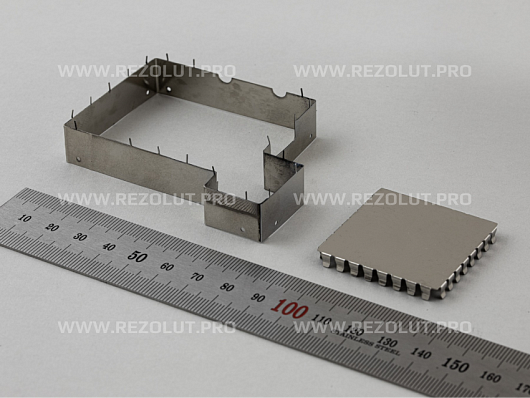

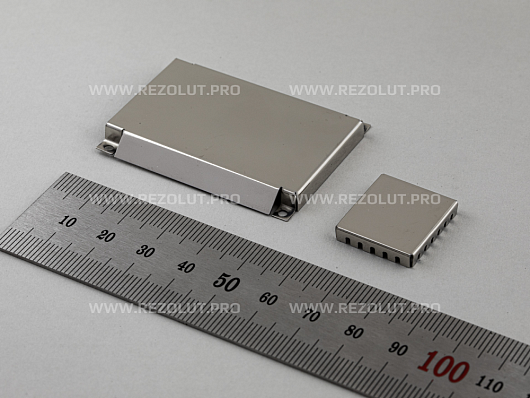

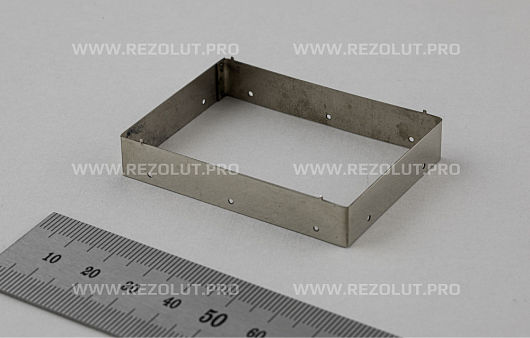

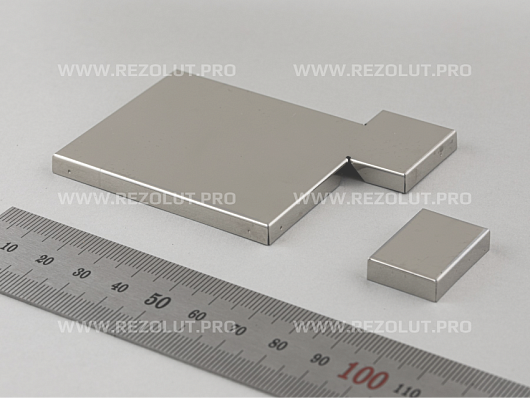

TWO-COMPONENT MOLDED RF SHIELDS

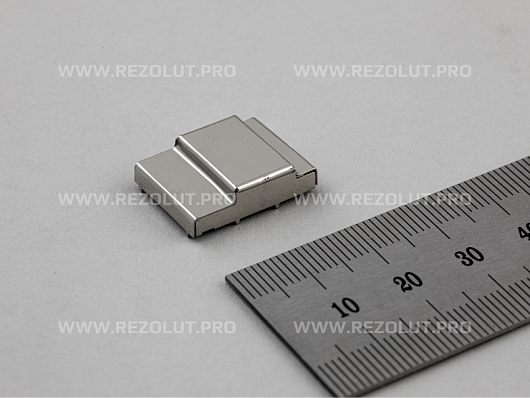

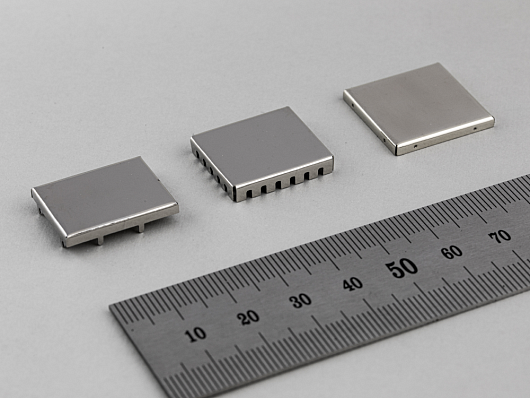

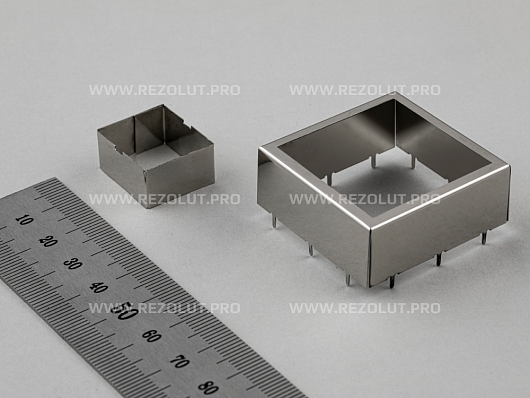

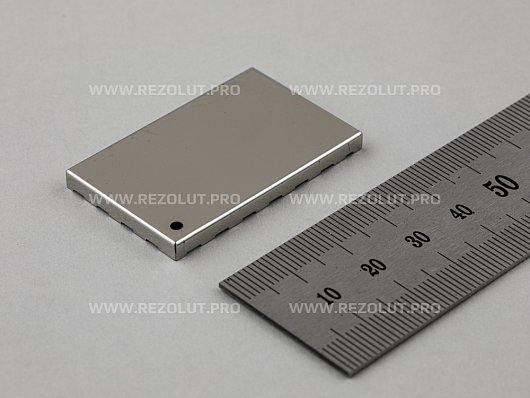

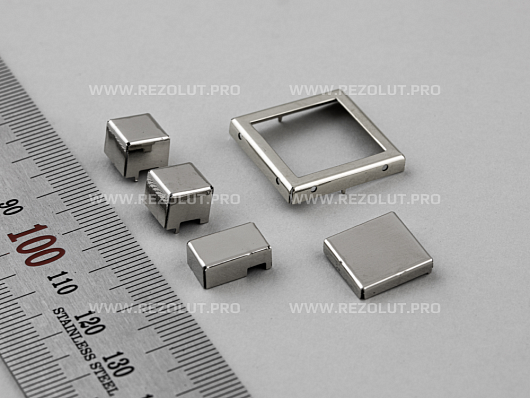

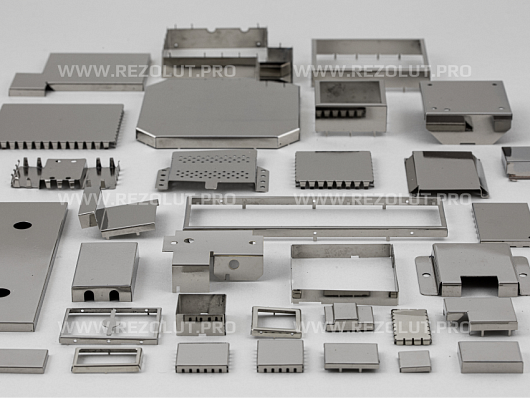

Two-component molded RF shields are attached to the board by mounting pins or by surface assembly. Brass, Alloy 770-nickel-silver, tinned sheet metal and stainless steel are the principal materials used. Thickness of the selected material can vary within the range of 0.15 to 0.6 mm, and the shield height from 4 to 12 mm. Corners are joined either arbitrarily or using “jalousie”-method and by virtue of laser welding. There is a possibility of copper, aluminum or titanium spraying as well as logo- and serial number application by way of silk-screen- and UV-printing and laser marking.

We are not limited by standard sizes and can produce RF shields using any technology and patterns required for your device.

shipment:

from 2 days

Leave a message

Contact us

leave a message

Need expert advice or get questions? Contact us, and our managers will get back to you shortly.