In the modern world, high-precision digital systems and high-frequency circuits are ubiquitous: from cellular phones to high-speed appliances and computer systems. Such appliances create considerable electric emissions which, in their turn, are translated either into radiofrequency or electromagnetic interference and, if not taken care of, could cause the systems’ glitch, failure and other negative consequences.

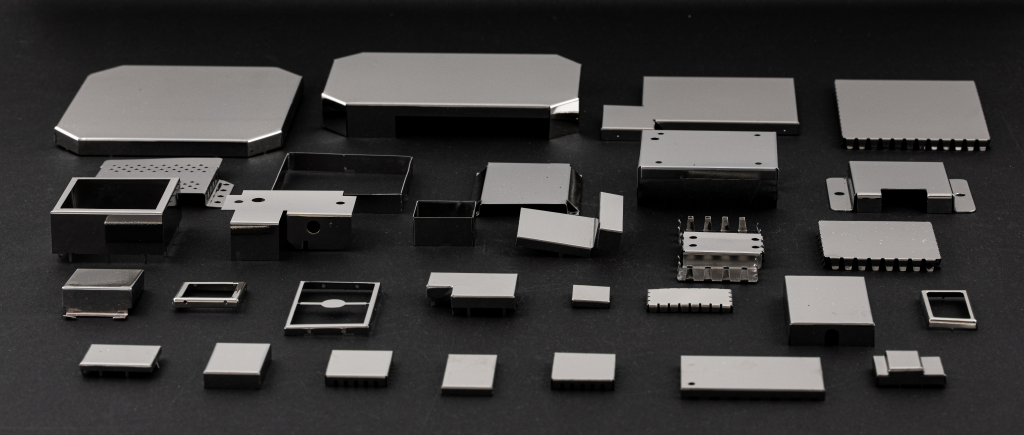

RF Shields by REZOLUT Company are an effective instrument of protection against such consequences for printed circuit boards. RF Shield effectiveness in various conditions is determined by several parameters: from the type of material used in the manufacturing process up to the physical structure of the shield proper. Besides, the material thickness as well as integrity of the item also determine the screen’s effectiveness level.

Steel, brass, nickel, copper, stainless steel and aluminum are the mostly used materials for RF Shield manufacturing. REZOLUT also offers tinned steel and brass shields that are easily soldered to printed circuit boards which provides for considerable economic effectiveness. Other materials used for RF Shield manufacturing should be coated immediately after manufacture completion. Meanwhile, the choice of suitable coating has a number of aspects:

- Electric characteristics (specific materials’ capacity to absorb EMI/RFI-emissions).

- Potential to withstand eventual environmental pressures (dust, humidity etc.).

- Mechanical aspects (specific materials' resistance towards dragging, bending, cutting etc.).

-

Cost of materials (both in terms of their composition as well as screen/PCB integration).

As regards REZOLUT Company, standard surface mounted shields are available both in one- as well as two-component versions. One-component shields provide protection against electromagnetic interference on six sides, the sixth side being the circuit board itself. Such constructs provide economically effective protection in places where the access to protected components is not required. Two-component shields allow for the possibility to check upon and repair protected components without risking to damage the PCB while removing the whole shield as well as avoiding extra costs of tool procurement. Covers are easily snapped shut and removed which speeds up and facilitates component repairs immediately under the shield preventing the repeated PCB conditioning.

We are not limited by standard item measurements and are capable of producing shields technologically and geometrically suitable for your electronic devices. Make your choice considering the PCB-measurements as well as contact configuration, and REZOLUT experts within hours will design the required shield, pick up the material and matching coating. Our solutions also include PCB-configuration, formulation of EMI-protection requirements as well as installation of grounding terminals. There is a possibility of serial number and logo placement by virtue of UV-, silk screen printing or laser marking.

Design is followed by prototyping. Preciseness and speed in this area are of utmost significance for successful end-product creation. Full-cycle production provides for test sample output within maximum three days. If any changes in product configuration are necessary, the design office will undertake to adjust the item measurements. To make sure that delivered components have the best suitable technical parameters corresponding with established requirements, all prototypes undergo 100-percent testing of their critically important measurements.

REZOLUT Company is considered one of the leading RF Shield suppliers in the CIS-market. The company effectively manages all stages of manufacturing cycle starting with raw materials and design and ending up with packaging and delivery. Localizing production in Belarus and Russia provides for speedy deliveries within the CIS-area.